Technical advantages of Induction Forging Furnace

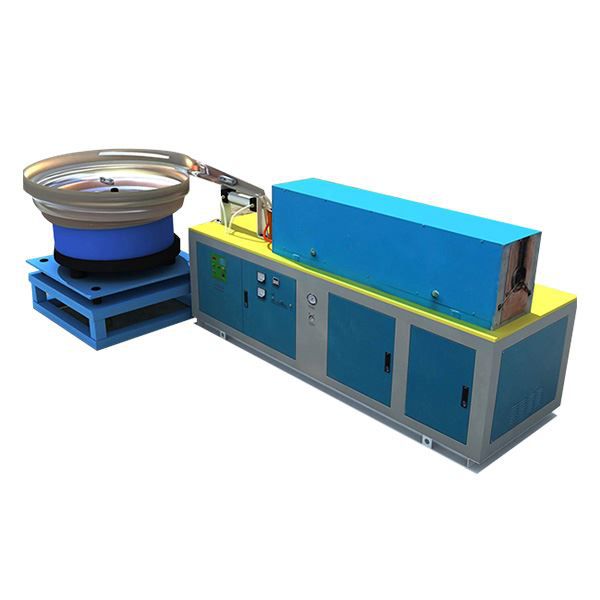

◆ The induction forging furnace is widely used in metal heating forging applications. Like the round bar, square billet, steel plate forging projects.

◆ High heating speed, high production efficiency, less oxidation, and decarburization, saving material, and forging die cost.

◆ Superior working environment, improve workers’ working environment and company image, no pollution, low energy consumption. Uniform heating, a small temperature difference of core gauge, high-temperature control precision.

◆ Energy-saving, small burning loss, easy to start.PLC control, touch screen man-machine interface, flexible operation, high reliability, strong anti-interference ability, easy maintenance, easy to upgrade.

What technical documents to provide for Induction Forging Furnace?

◆ Equipment layout, foundation diagram, water circuit diagram.

◆ Electrical schematic diagram and external wiring diagram

◆ Control electrical schematic diagram

◆ Equipment operation and maintenance instructions

◆ Main outsourcing parts, parts specifications

◆ Equipment inspection certificate, ex-factory packing list.

How to maintain induction forging furnace?

◆ Always remove dust from the induction forging furnace power cabinet.

◆ Check and maintain the equipment regularly, check and tighten the bolts and pressing parts of each part.

◆ Periodically check the overcurrent value and overvoltage value of the device, check the reliability of the operation of the protection system, and prevent the protection failure.

◆ Always check whether the load wiring is in good condition and the insulation is reliable.

◆ Frequently check whether the water pipe joint is firm, timely clean the scale, and plug in the cooling water pipe.

FAQ

◆ The induction forging furnace is automatic or others?

Mostly we do the automatic ones, but as per the user’s request can customize different forging furnace.

◆ How about the heating forging result?

The workpiece is heated uniformly, the temperature difference of the core gauge is small, and the temperature control precision is high.

◆ Is it green for the environment?

Yes. It is. Meet the environmental protection requirements, low energy consumption, low pollution.